Battery Transfer Cart Brushless DC Motor Drive System

The battery transfer cart brushless DC motor drive system overcomes the defects of the brushless DC motor system or the inverter + asynchronous motor system, and improves the electric transfer cart drive technology to a new height.

The system includes: brushless DC motor + controller, which can easily realize forward / backward, stepless speed regulation, soft start, electronic EABS brake, parking brake, remote control and other functions. It has complete equipment, overall debugging test, excellent performance and convenient use. For KPD low-voltage rail electric flat cart, the special AC-DC rectifier module developed by our company can be selected. The 36V single-phase AC is about 50V DC after rectification, which directly supplies power to DC motor. It can overcome the problems of rail AC motor, such as long track, large voltage drop, difficult starting of transfer cart with load and so on. It is especially suitable for long-distance rail operation. Safe and convenient.

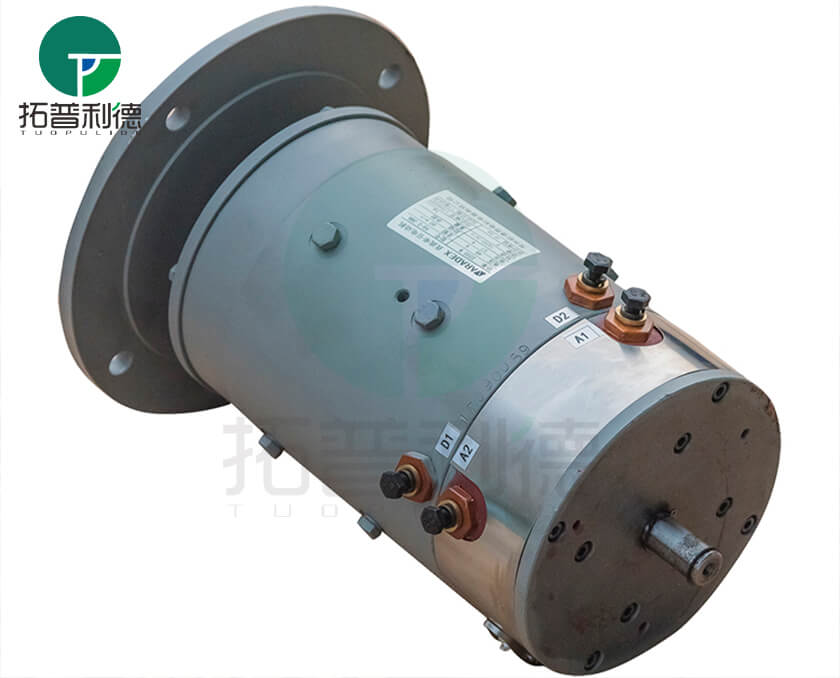

Brushless DC motor has no carbon brush structure, no spark, no need to replace carbon brush, protection grade: IP44, water, mud, soil will not enter the motor, compact structure, strong overload capacity, long service life.

Special slow start and EABS brake: the starting process of permanent magnet brushless motor is smooth, soft and powerful. Adjustable slow start time; soft, accurate and safe braking stop process. Perfect for loading round objects.

There is no hidden danger in the brushless system: there is no step-up transformer on the flat car, and there is no dangerous high voltage. After rectification, the AC 36v rail power is only about 50V DC, so there is no hidden danger, and it will not cause electric shock accidents.

Low carbon and energy saving: permanent magnet brushless motor has small volume, light weight, less heating and high efficiency. Meet the requirements of national energy conservation and emission reduction. It is the upgrading product of DC brush motor and AC asynchronous motor. In the frequent start and stop occasions, the operation efficiency of AC asynchronous motor is more than 25% higher than that of DC brush motor. It is a kind of green environmental protection motor.

High reliability: brushless motor system waterproof, moisture-proof, dust-proof, shockproof, high temperature, maintenance free. The controller and rectifier module are imported from Germany, and the reliability is far higher than the industrial level. After strict high temperature aging test, the motor runs more smoothly, has less heating, lower noise, higher efficiency, reliable performance and normal service life of more than 50000 hours.

Excellent load characteristics, good low-speed performance, large starting torque, small starting current, adapt to the needs of frequent starting of electric vehicles, save electric energy. The motor runs efficiently in the whole speed range, which is better than the brushless DC motor and the AC variable frequency motor (the efficiency is higher only near the rated point).

Pulse power consumption, in line with the characteristics of battery discharge, does not need the battery to output large current instantaneously to prevent the battery from losing power instantaneously. Compared with the brushless DC motor or AC variable frequency motor, it can run 30% ~ 50% more mileage in one charge and increase the service life of battery by 50%.

The motor adopts insert type rare earth magnetic steel, and the permanent magnet adopts 180 degree high temperature resistant rare earth permanent magnet. It can work safely and reliably in extremely harsh environment. Especially suitable for bumpy, repeated start, high speed, large torque start, forward and reverse operation.

Excellent speed regulation performance, full load stepless speed regulation in full speed range.

The motor adopts imported oil-bearing high-speed bearing, maintenance free, high reliability and long service life. The motor has horizontal and suspended type, with convex edge end cap, double shaft extension and spline shaft extension. The brushless motor drive system with various voltage, speed and power requirements can be customized according to customer requirements.

It is easy to install and use, and seamless docking with remote control and industrial operation handle.