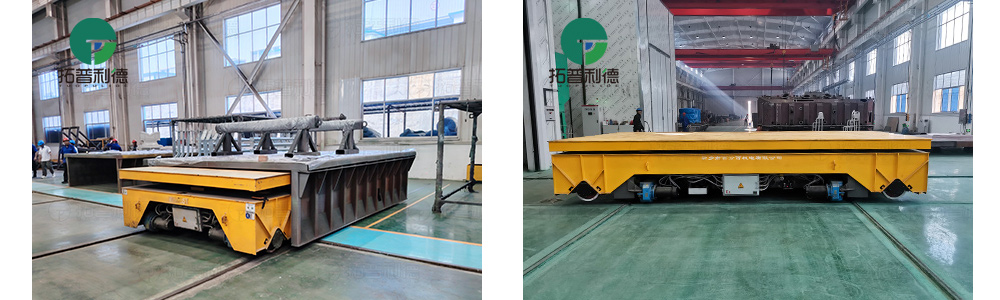

35 Tons Rail Transfer Cart with Hydraulic Lifting Table for Mold Handling

Production Challenge

In a large heavy duty equipment manufacturing workshop, the facility faced challenges such as low efficiency in cross-area transportation of large workpieces (single piece weighing up to 32 tons), limitations in traditional crane scheduling, and safety risks associated with manual operations.

Solution

Based on the customer's actual working conditions and usage requirements, we designed and manufactured this 35 tons battery powered vertical and horizontal movement rail transfer cart.

The cart combines features such as high temperature resistance, precise docking, and free lifting, allowing it to flexibly adapt to production needs.

The cart adopts a box-girder robust frame and a dual-motor drive system, paired with heavy duty cast steel wheels, ensuring structural stability and durability under high loads.

Operation Method: Utilizing wireless remote control and an intelligent coding control system, operators can flexibly command the vehicle from a distance, executing instructions such as forward, reverse, traversing, and speed adjustment.

Intelligent Safety: The transfer cart is equipped with a custom hydraulic lifting platform that can automatically dock with production line stations, enabling autonomous loading and unloading of workpieces.

An explosion proof housing and audible/visual warning lights provide dual protection for safe operation in complex working conditions, while an LED screen and power display monitor real-time operational status and energy data for easy management.

Application

- In the production workshop, operators can monitor the equipment in real-time via wireless remote control and make immediate adjustments based on mold positions and corresponding transfer routes.

- The hydraulic lifting platform automatically adjusts its height to dock with and handle materials for autonomous loading/unloading. The cast steel wheels enable traversing movement across different tracks. The explosion proof housing effectively ensures workshop safety, and the audible/visual warning lights combined with an emergency stop button serve to alert personnel and enable emergency braking.

- The power display continuously monitors battery status. This achieves autonomous handling and precise transportation of 35 tons workpieces, with high temperature resistance adapting to the hot workshop environment and eliminating the need for frequent charging.

The transfer cart solves the problems of time-consuming manual loading/unloading and high risks in heavy load transportation. Single-trip transfer time is reduced to 8 minutes, and labor costs are lowered by 30%.

Suitable for various scenarios such as production workshops and factory yards, it has become a reliable choice for heavy workpiece handling, helping enterprises reduce costs, improve efficiency, and ensure safe operations.